Betonfertigbäder Made in Germany

Erst das Bad verleiht einer Immobilie seinen einzigartigen Charme. Doch treffen Termin- und Kostendruck bei Großbauprojekten aufeinander, stoßen Bauherren, Planer und ausführende Unternehmen im Bauprozess an ihre Grenzen. Mit unserer jahrzehntelangen Bad-Kompetenz lösen wir bei Rasselstein Raumsysteme die Herausforderungen während der Planungs- und Bauphase auf.

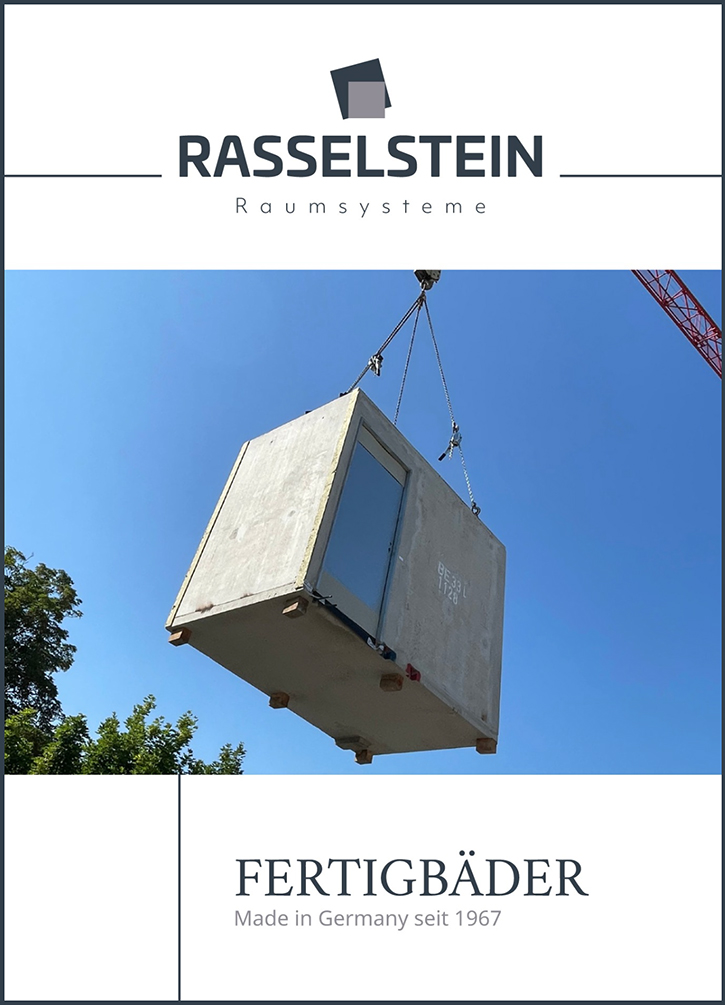

Mit unseren hochwertigen Betonfertigbädern liefern wir die passende Lösung nach individuellen Vorgaben. Insbesondere bei hohen Stückzahlen baugleicher Bäder spielt unser Fertigbad-Konzept seine Vorteile aus. Wir bündeln verschiedene Gewerke in nur einem Ansprechpartner und führen sie zentral in unserer eigenen Produktion aus. Sie bringen sie einfach Plug&Play in Ihr Bauprojekt ein. Beauftragen Sie Qualitätsarbeit made in Germany mit dem herausragenden Baustoff Beton. Vertrauen Sie Rasselstein Raumsysteme.

Wirtschaftliche Badsysteme, bei denen alles passt!

Warum kompliziert, wenn es auch einfach geht? Oder warum konventionell, wenn es auch vorgefertigt geht? In hoher Stückzahl in typengleichem Design produziert, reduzieren sie die Komplexität in der Planung und am Bau. Dadurch entkommen Bauherren, Planer und Bauunternehmen hohem Kosten- und Termindruck in Planungs- und Bauphase.

Das Betonfertigbad – Garant für Effizienz und Qualität

- TÜV-geprüfte Qualität

- Zehn Gewerke aus einer Hand

- Serienmäßige Fertigung mit gleichbleibend hoher Qualität

- Reduzierung der Komplexität in Planung und Realisierung

- Vereinfachte Baustellenlogistik, Entlastung der Bauleitung

- Termin- und Kostensicherheit

Premiumlösung nach Ihren Bedürfnissen!

Rasselstein Raumsysteme steht für Premium-Fertigbäder aus hochwertigem stahlarmierten Beton. Unsere besondere Baustoff-Rezeptur macht den Unterschied. Mit unserem jahrzehntelangen Know-how haben wir Betonfertigbäder kontinuierlich weiterentwickelt und auf die Bedürfnisse unserer Partner angepasst. Dadurch vereinen wir Qualität, Funktionalität und Design. Kurze Produktionszeiten, zertifizierte Systemqualität und einfache Baustellenabwicklung zählen zu unseren Stärken.

Sie wünschen eine unverbindliche Beratung?

Wir beraten Sie gerne persönlich zu unseren Betonfertigbädern und finden für Sie das richtige Produkt.

© 2021 Rasselstein Raumsysteme GmbH & Co. KG